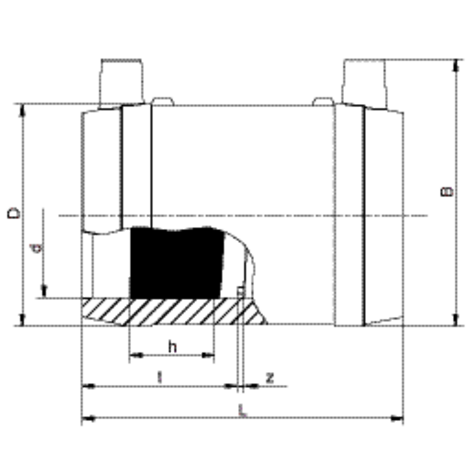

| Κωδικός προϊόντος | d | BX | PU | D | t | z | h | B | Weight kg |

|---|---|---|---|---|---|---|---|---|---|

| 612680 | 20 | 110 | 3520 | 33 | 29 | 2 | 17 | 49 | 0,040 |

| 612681 | 25 | 100 | 3200 | 38 | 32 | 2 | 17 | 54 | 0,060 |

| 612682 | 32 | 80 | 2560 | 45 | 38 | 2 | 21 | 61 | 0,070 |

| 612683 | 40 | 40 | 1280 | 54 | 42 | 2 | 23 | 71 | 0,090 |

| 612684 | 50 | 25 | 800 | 68 | 48 | 2 | 27 | 82 | 0,150 |

| 612685 | 63 | 18 | 576 | 82 | 55 | 2 | 29 | 96 | 0,230 |

| 612686 | 75 | 50 | 400 | 98 | 60 | 3 | 32 | 110 | 0,330 |

| 612687 | 90 | 40 | 320 | 114 | 77 | 3 | 51 | 127 | 0,440 |

| 612688 | 110 | 24 | 192 | 137 | 78 | 3 | 49 | 152 | 0,710 |

| 612689 | 125 | 18 | 144 | 156 | 85 | 3 | 51 | 169 | 0,940 |

| 612690 | 140 | 12 | 96 | 174 | 91 | 3 | 52 | 185 | 1,270 |

| 612691 | 160 | 8 | 64 | 199 | 94 | 3 | 52 | 207 | 1,780 |