Spigot Σέλα SA XL

Για ολοκληρωμένη γραμμής διακλάδωσης ή εξαερισμού σε σωλήνες PE με μεγάλη διάμετρο - χωρίς πίεση ή υπό πίεση λειτουργίας. Συμπαγής σέλα κατασκευασμένη από PE-HD με εκτεθειμένη θερμαντική αντίσταση για βέλτιστη μεταφορά θερμότητας. Έξοδος για επεξεργασία με FRIALEN MB ή UB.

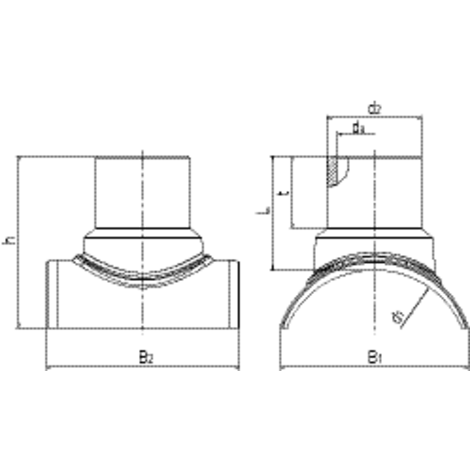

For integration of a branch line or vent in PE pipelines with large diameters –unpressurised or under operating pressure. Compact fitting made of HD-PE. Saddle with exposed heating element for optimal heat transfer. Outlet spigot for processing with FRIALEN couplers MB or UB.

The SA XL spigot saddle is assembled using a FRIATOOLS vacuum pump (see left application picture; order no. 613827) and the corresponding FRIATOOLS plunger (see Product Range FRIATOOLS).

Tapping in unpressurised condition with FRIATOOLS tapping kit FWAB XL (see right application picture and Product Range FRIATOOLS) or, using an additional shut-off valve, under operating pressure using commercially available drilling equipment (we recommend Hütz & Baumgarten: www.huetz-baumgarten.de).

For tapping under pressure, please contact our hotline: +49 621 486-2325.

| Κωδικός προϊόντος | product.detail.attribute.d1Small | d2 | BX | PU | L | t | h | B1 | B2 | Drilling Ø da |

Weight kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 616469 | 400 | 225 | 1 | 4 | 263 | 210 | 403 | 483 | 530 | 172 | 14,700 |

| 616779 | 400 | 250 | 1 | 4 | 261 | 210 | 417 | 483 | 530 | 187 | 15,200 |

| 616780 | 450 | 225 | 1 | 4 | 267 | 210 | 421 | 530 | 530 | 172 | 17,500 |

| 616781 | 450 | 250 | 1 | 4 | 272 | 210 | 426 | 530 | 530 | 187 | 18,000 |

| 616391 | 500 | 225 | 1 | 4 | 265 | 210 | 388 | 521 | 530 | 172 | 14,500 |

| 616782 | 500 | 250 | 1 | 4 | 263 | 210 | 380 | 521 | 530 | 187 | 15,500 |

| 616783 | 500 | 280 | 1 | 4 | 265 | 210 | 388 | 521 | 590 | 225 | 15,600 |

| 616784 | 500 | 315 | 1 | 4 | 268 | 210 | 446 | 573 | 590 | 254 | 21,600 |

| 616392 | 560 | 225 | 1 | 4 | 263 | 210 | 402 | 577 | 530 | 172 | 15,700 |

| 616785 | 560 | 250 | 1 | 4 | 263 | 210 | 398 | 577 | 530 | 187 | 17,000 |

| 616786 | 560 | 280 | 1 | 4 | 265 | 210 | 404 | 577 | 590 | 225 | 17,000 |

| 616787 | 560 | 315 | 1 | 4 | 268 | 210 | 402 | 564 | 590 | 254 | 19,800 |

| 616788 | 560 | 355 | 1 | 4 | 260 | 210 | 451 | 618 | 630 | 286 | 26,000 |

| 616789 | 560 | 400 | 1 | 4 | 260 | 210 | 451 | 618 | 630 | 322 | 27,200 |

| 616393 | 630 | 225 | 1 | 4 | 265 | 210 | 422 | 634 | 530 | 172 | 17,000 |

| 616790 | 630 | 250 | 1 | 4 | 267 | 210 | 419 | 634 | 530 | 187 | 17,500 |

| 616791 | 630 | 280 | 1 | 4 | 263 | 210 | 420 | 634 | 590 | 225 | 18,000 |

| 616792 | 630 | 315 | 1 | 4 | 265 | 210 | 417 | 621 | 590 | 254 | 20,900 |

| 616793 | 630 | 355 | 1 | 4 | 269 | 220 | 422 | 616 | 630 | 286 | 23,800 |

| 616794 | 630 | 400 | 1 | 4 | 267 | 220 | 419 | 616 | 630 | 322 | 25,000 |

| 616394 | 710 | 225 | 1 | 4 | 270 | 210 | 447 | 712 | 530 | 172 | 20,500 |

| 616795 | 710 | 250 | 1 | 4 | 265 | 210 | 437 | 712 | 530 | 187 | 22,100 |

| 616796 | 710 | 280 | 1 | 4 | 268 | 210 | 445 | 712 | 590 | 225 | 21,500 |

| 616797 | 710 | 315 | 1 | 4 | 268 | 210 | 439 | 694 | 590 | 254 | 23,800 |

| 616798 | 710 | 355 | 1 | 4 | 285 | 220 | 457 | 694 | 630 | 286 | 28,500 |

| 616762 | 710 | 400 | 1 | 4 | 275 | 220 | 447 | 694 | 630 | 322 | 29,500 |

| 616395 | 800 | 225 | 1 | 4 | 270 | 210 | 381 | 643 | 530 | 172 | 17,300 |

| 616799 | 800 | 250 | 1 | 4 | 275 | 210 | 384 | 643 | 530 | 187 | 18,600 |

| 616800 | 800 | 280 | 1 | 4 | 268 | 210 | 382 | 643 | 590 | 225 | 18,600 |

| 616801 | 800 | 315 | 1 | 4 | 268 | 210 | 377 | 629 | 590 | 254 | 20,500 |

| 616802 | 800 | 355 | 1 | 4 | 290 | 220 | 483 | 772 | 630 | 286 | 31,200 |

| 616803 | 800 | 400 | 1 | 4 | 275 | 220 | 468 | 772 | 630 | 322 | 31,600 |

| 616396 | 900 | 225 | 1 | 4 | 268 | 210 | 396 | 714 | 530 | 172 | 19,000 |

| 616804 | 900 | 250 | 1 | 4 | 278 | 210 | 402 | 714 | 530 | 187 | 20,700 |

| 616805 | 900 | 280 | 1 | 4 | 268 | 210 | 396 | 714 | 590 | 225 | 20,300 |

| 616806 | 900 | 315 | 1 | 4 | 269 | 210 | 393 | 700 | 590 | 254 | 23,000 |

| 616807 | 900 | 355 | 1 | 4 | 305 | 220 | 429 | 700 | 630 | 286 | 27,300 |

| 616808 | 900 | 400 | 1 | 4 | 275 | 220 | 399 | 700 | 630 | 322 | 28,000 |

| 616397 | 1000 | 225 | 1 | 4 | 270 | 210 | 396 | 653 | 530 | 172 | 18,000 |

| 616809 | 1000 | 250 | 1 | 4 | 280 | 210 | 366 | 653 | 530 | 187 | 19,300 |

| 616810 | 1000 | 280 | 1 | 4 | 270 | 210 | 361 | 653 | 590 | 225 | 19,000 |

| 616811 | 1000 | 315 | 1 | 4 | 270 | 210 | 358 | 642 | 590 | 254 | 21,000 |

| 616812 | 1000 | 355 | 1 | 4 | 305 | 220 | 444 | 774 | 630 | 286 | 30,800 |

| 616813 | 1000 | 400 | 1 | 4 | 278 | 220 | 417 | 774 | 630 | 322 | 31,300 |

| 616384 | 1200 | 225 | 1 | 4 | 270 | 210 | 346 | 655 | 530 | 172 | 17,500 |

| 616814 | 1200 | 250 | 1 | 4 | 284 | 210 | 354 | 655 | 530 | 187 | 19,200 |

| 616815 | 1200 | 280 | 1 | 4 | 270 | 210 | 345 | 655 | 590 | 225 | 18,600 |

| 616816 | 1200 | 315 | 1 | 4 | 270 | 210 | 343 | 645 | 590 | 254 | 20,800 |

| 616817 | 1200 | 355 | 1 | 4 | 305 | 220 | 413 | 759 | 630 | 286 | 29,600 |

| 616818 | 1200 | 400 | 1 | 4 | 278 | 220 | 385 | 759 | 630 | 322 | 30,300 |

| Κωδικός προϊόντος | product.detail.attribute.d1Small | d2 | BX | PU | L | t | h | B1 | B2 | Drilling Ø da |

Weight kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 616378 | 1000 | 160 | 1 | 4 | 300 | 249 | 390 | 654 | 530 | 123 | 17,350 |

| 616383 | 1200 | 160 | 1 | 4 | 300 | 250 | 375 | 655 | 530 | 123 | 17,200 |

Areas of Application

Create highly economical branches!

Instead of cost-intensively integrating a T-piece, a branch or vent can be very comfortably created using the new FRIALEN XL spigot saddle SA XL.

Assembly Instructions

A simple assembly, comfortable handling and short processing time characterise the optimised and construction site-appropriate clamping method for large saddle component parts.

Branch saddle as branch: Your benefit – simple assembly!

The spigot saddles SA XL permit creating also large-volume branches at main pipes - unpressurised or under operating pressure - with less effort, minimal underground work and above all without interrupting the supply.

The saddle can be fixed at any position on the pipe. Thanks to the clamping method specifically developed for SA XL, only access to the covered saddle area is required. Specifically in the case of connections to existing pipelines, the bedding in the pipeline zone is only disturbed as absolutely necessary.

Vacuum clamping technology: Your benefit – comfortable handling!

The clamping force of the saddle required for fusion and built-up of the joining pressure is applied by a vacuum. This only requires a compressor usual for construction sites and the VACUSET. Out-of-roundnesses and shape deviations of the pipe usually seen at construction sites can be bridged by the clamping method.

But it is above all the required space in the pipe trench – and thus cost-intensive underground work – which is minimised for access to the pipe.

The tapping diameter is almost identical with the pipe’s diameter of the outlet spigot such that pressure losses are minimised.

Thanks to the use of preheating technology, the two joining partners (pipe surface and saddle area) are uniformly adjusted.

Your benefit: Little time required!

Commissioning is possible with only a few actions. Short assembly and fusion times, short cooling times and a quick tapping permit a branch to be completed in almost no time at all!

Good reasons for using FRIALEN XL Spigot Saddle

SA XL:

Compact construction

HD-PE saddle with exposed heating element for optimal heat transfer

Low tapping forces

Burr-free and almost flush tapping for maximum hydraulic performance

Leakage free tapping possible by means of a shut-off element

Extra wide fusion zone

Additional barcode for tracing back the underground fitting (Traceability-Coding)

Touch proof electric contacts

Easy and safe assembly by vacuum clamping technology

Preheating technology for optimum alignment of the joining partners

Fusion indicators for visual fusion control

Durable batch marking

Individually wrapped for dirt protection

product.detail.headline.accessories