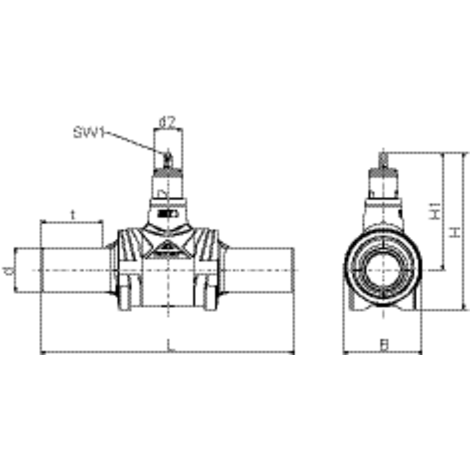

PE shut-off valve without flow losses (closing in an anti-clockwise direction)

Shut-off valve FRIALOC ACW

- Water

- Maximum pressure: 16 bar

- Material: PE 100

- Double shut-off function

- No cavities and stagnation

- No flow losses

- Maximum 14 turns for opening and closing

- Closing operation, anti-clockwise

- DVGW test mark: DW-6210BT0171

Note:

The nominal sizes 200 to 225 have a limited passage of d 180.

There is a suitable installation kit FBS with KlickFix for wrench size SW19 (19 mm).

Value da is the maximum tapping diameter of the external tapping device.

PE 100 SDR 11

Maximum permissible working pressure 16 bar (water)

| Reference | d | d2 | BX | PU | L | t | B | sw1 | H1 | H | Turns open/close |

Weight kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 616991 | 90 | 80 | 1 | 8 | 720 | 158 | 225 | 19 | 335 | 450 | 9 | 13,900 |

| 616992 | 110 | 80 | 1 | 8 | 720 | 164 | 225 | 19 | 335 | 450 | 9 | 14,200 |

| 616993 | 125 | 80 | 1 | 8 | 720 | 174 | 225 | 19 | 335 | 450 | 9 | 14,500 |

| 616994 | 160 | 80 | 1 | 2 | 1010 | 196 | 330 | 19 | 450 | 608 | 14 | 37,900 |

| 616995 | 180 | 80 | 1 | 2 | 1030 | 210 | 330 | 19 | 450 | 608 | 14 | 39,000 |

| 616996 | 200 | 80 | 1 | 2 | 1030 | 120 | 330 | 19 | 450 | 608 | 14 | 40,500 |

| 616997 | 225 | 80 | 1 | 2 | 1030 | 124 | 330 | 19 | 450 | 608 | 14 | 40,500 |

Please note the mandatory labels directly on the product.

da: max. tapping diameter of the external tapping device

Range of use / application

FRIALOC ACW is used as shut-off valve in water piping systems. The free passage of the PE shut-off valve shows no constrictions with regard to the connecting pipe SDR 11. Actuation is made from the street cap using the installation kit FBS. Thanks to the innovative shut-off mechanism, activation is possible with only a few turns and without major force (anti-clockwise closing). For further information see this data sheet page 2 or data sheet installation kit FBS No. 63/07.

Notes on processing

The FRIALOC ACW shut-off valve made of polyethylene is homogeneously connected to the PE piping by FRIALEN fusion, using FRIALEN safety fittings. This requires no gaskets, material transitions, or mechanical connections. The homogeneous joint is permanently leak-tight and friction-locked. Corrosion protection is not required. The shut-off valve can also be integrated into existing piping networks made of other materials, e.g. using flanges.

Please observe the notes on the installation of the FRIALOC ACW shut-off valve in the FRIALEN assembly instructions for house service and supply pipings up to d 225.

Good reasons for using the FRIALOC ACW:

- FRIALOC ACW facilitates the completely fused and homogeneous PE piping without flanges and material transitions

- Typically PE: no corrosion, no incrustation

- Innovative two-flap mechanism for a reliable shut-off under all operating conditions

- Low-wear drive: proven in fatigue test by 2,500 dynamic test cycles under maximum pressure

- Hygiene: no stagnating water, minimised sealing area

- Corrosion-resistant metal materials

- Significant weight saving compared to metal valves

- Special contour for a pull-tight and dirt-proof connection to the protective pipe of the FRIALEN-FBS

- Low actuation forces, smooth-running even given under full differential pressure

- FRIALOC ACW actuate by anti-clockwise closing

- Few turns for opening/closing

- Optimal hydraulics thanks to a full-port passage, no constrictions

- Stable support in the ditch bottom thanks to large support area

- Length of connecting d 90-d 180 couplers designed for two fusion processes, can be reduced for compact shape

- Each single shut-off valve is inspected by the factory after mounting

- Production data are saved, archived, and can be documented via a traceability barcode

get_app

get_app

get_app

get_app