Vacuum-loading transition saddle

Transition saddle, Vacuum-Loading ASA VL KG 160, SDR 17

- Compact component made from HD-PE with integral socket in the outlet (d 160)

- For connecting connecting pipes made of PVC/PP DN 150 to existing PE main channel

- Safety technology

Note:

Can only be fused with the clamping system FRIALOAD.

Components: PUMP (Order No. 613810), PLATE (Order No. 617372) and FWAB ASA VL 160/450 (Order No.613846) or FWAB ASA VL 160/710 (Order No. 613816).

For installation on close-fit liners and pipes d 560/d 630, please contact our hotline +49 621 486-2325.

PE 100

Maximum permissible test pressure 0.5 bar according to DIN EN 1610

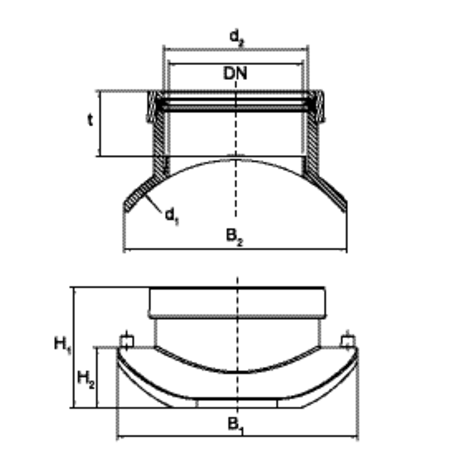

| Reference | d1 | d2 | Nominal diameter | BX | Pallet quantity | t | H1 | H2 | B1 | Weight [kg] | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 682646 | 225 | 160 | 150 | 10 | 80 | 76 | 163 | 92 | 270 | 1,060 | |

| 682625 | 250 / 280 | 160 | 150 | 10 | 80 | 76 | 143 | 72 | 270 | 1,040 | |

| 682652 | 315 | 160 | 150 | 10 | 80 | 76 | 143 | 72 | 270 | 1,060 | |

| 682627 | 355 | 160 | 150 | 10 | 80 | 76 | 129 | 58 | 270 | 1,060 | |

| 682657 | 450 | 160 | 150 | 10 | 80 | 76 | 129 | 58 | 270 | 0,990 | |

| 682629 | 500/560/630 | 160 | 150 | 10 | 80 | 76 | 117 | 46 | 270 | 0,940 | |

| 682666 | 560 | 160 | 150 | 10 | 80 | 76 | 113 | 42 | 270 | 1,120 | |

| 1 | 682668 | 630 | 160 | 150 | 10 | 80 | 76 | 110 | 39 | 270 | 1,120 |

| 1 | 682665 | 710 | 160 | 150 | 10 | 80 | 76 | 107 | 36 | 270 | 1,120 |

Sewage pipe systems are high-value assets of a value which has to be maintained for a long time. Increasing demands on the public sewage system require materials which meet these criteria. HDPE sewage pipes have been fused for many years with the FRIAFIT HDPE sewage system tightly, frictionlocked and root-proof.

Areas of application

House service connections to HDPE sewers: Direct transition option of house service pipings made of PVC/PP by using the integrated plug-in sleeve DN 150. The plug-in sleeve has a SBR lip seal and a large insertion depth for a secure guiding of the pipe.

The FRIAFIT transition saddle ASA VL 160 KG facilitates the production of sewage house service connections without having to disconnect the existing HDPE sewer.

Assembly Instructions with vaccum clamping

The clamping force of the saddle required for fusion and build-up of the joining pressure is applied by a vacuum. This only requires the clamping device FRIALOAD. Typical out-of-roundnesses and shape deviations of the pipe can be bridged by the clamping method.

Good reasons for the FRIAFIT transition saddle ASA VL 160 KG

Saddle element

- Economic production of house service connections, in particular in case of a high building coverage

- Possible applications for new installation, refurbishment, and later connection of drain pipes

- Little space required thanks to compact component part, PVC / PP connecting pipes can be directly inserted into the sleeve element

- Direct connection of the connecting pipes without interfering displacement or drain obstructions

- Economic processing with the clamping device FRIALOAD

- Barcode for fully automatic fusion with HDPE pipes from SDR 33 to SDR 11, taking into consideration the ambient temperature (temperature compensation)

- Exposed, fixed heating coil for direct heat transfer to the pipe

Plug-in sleeve element

- Safe guiding of the PVC / PP pipe thanks to a large insertion depth

- SBR lip seal according to EN 681-1

- Standardised material transition

Downloads

Accessories

get_app

get_app

get_app

get_app